HEINZMANN

Engine & Turbine Management

HEINZMANN Electric Drives

Robust electric motors

REGULATEURS EUROPA

Control & Monitoring

HEINZMANN China

Control & Actuation

HEINZMANN UK

Gas & Water Turbine Control

HEINZMANN Australia

Steam Turbine Control

CPK Automotive

Emission Control

Giro Engineering

Diesel Engine Components

HEINZMANN IFT GmbH

Oil Mist Separators and Blow-by Filter Technology

Reduce costs & increase

decarbonization by

OPTIMISING THE PERFORMANCE

OF YOUR ENGINE

HEINZMANN Automation - Experts in Engine Management!

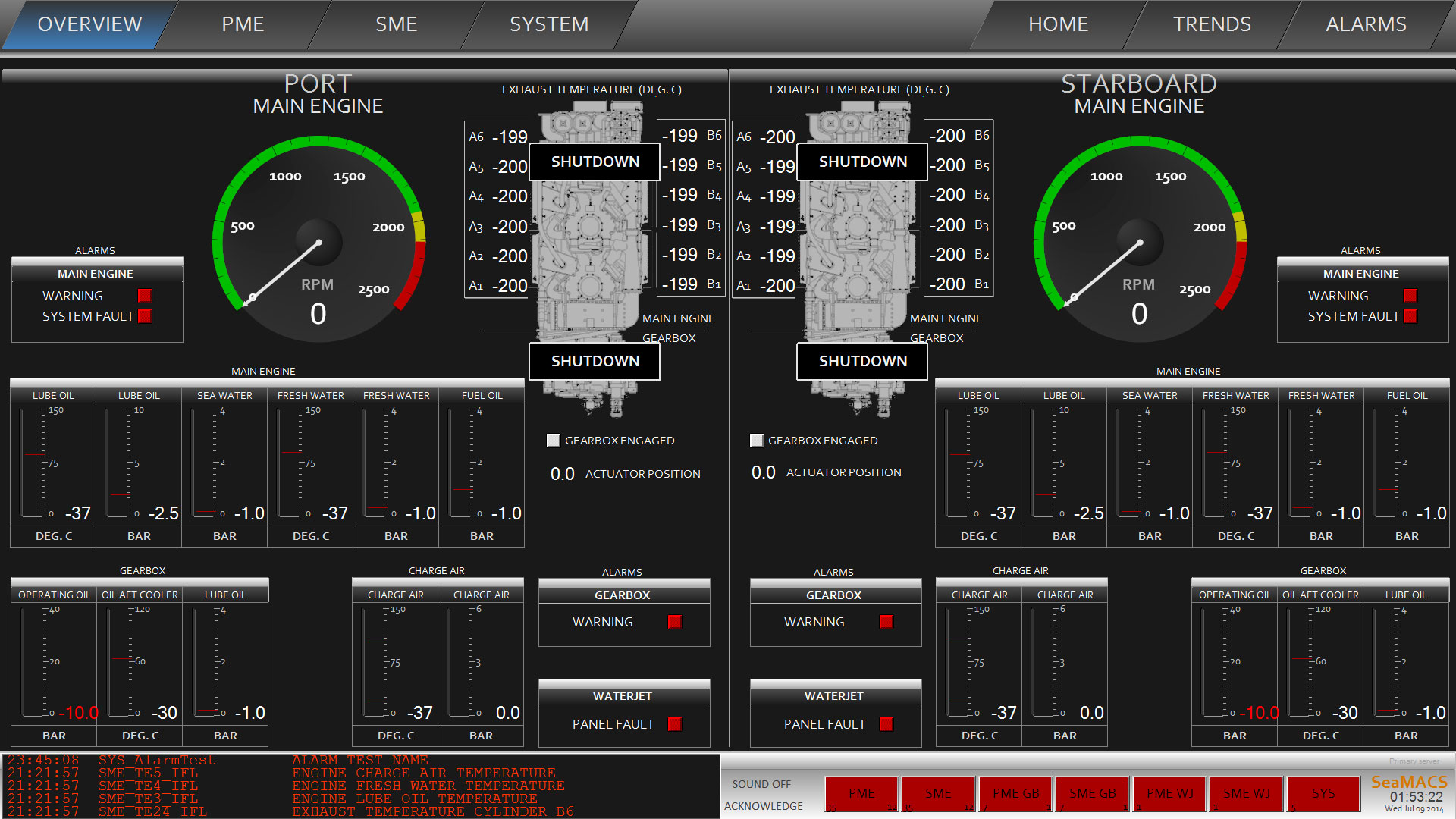

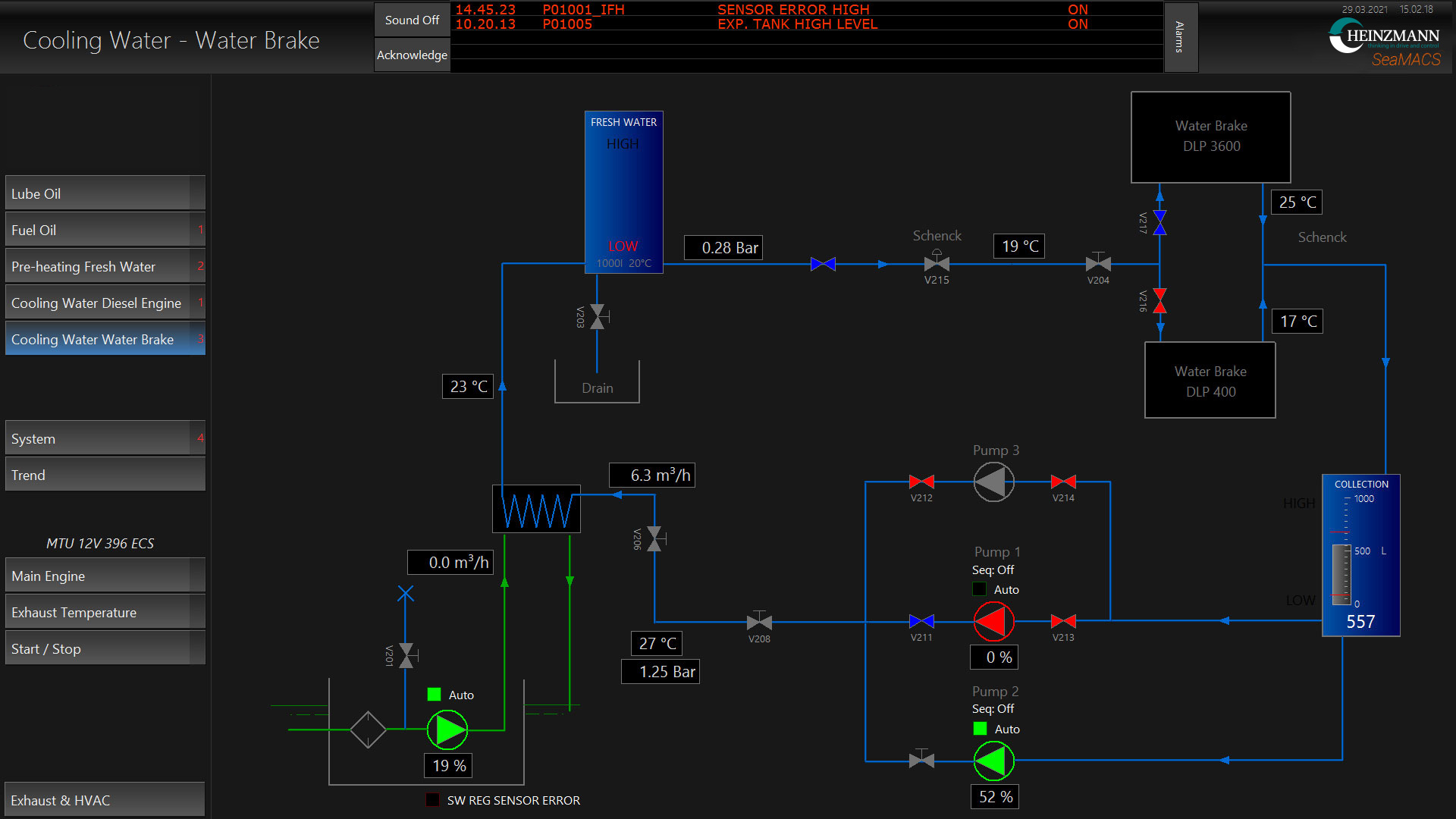

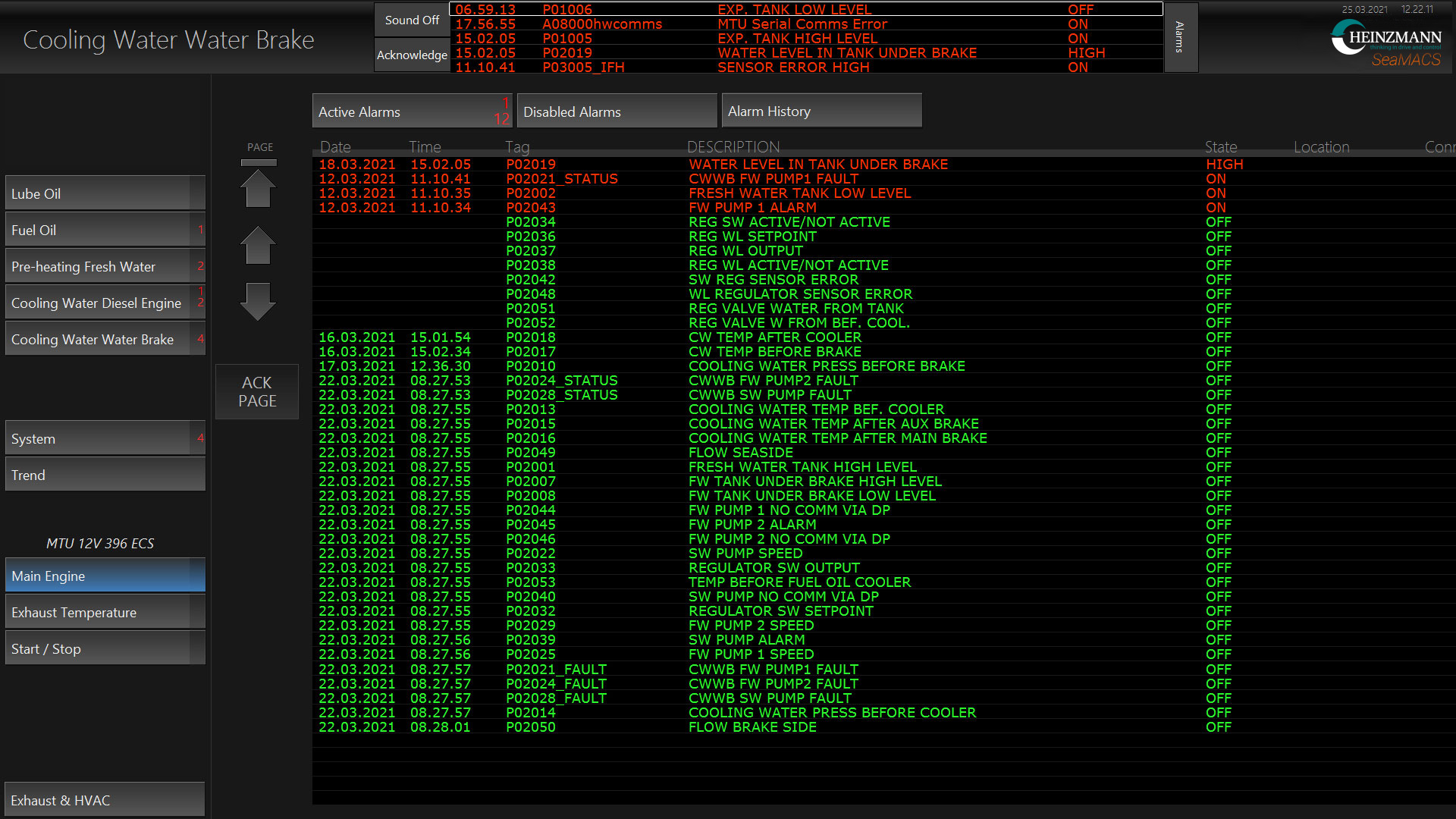

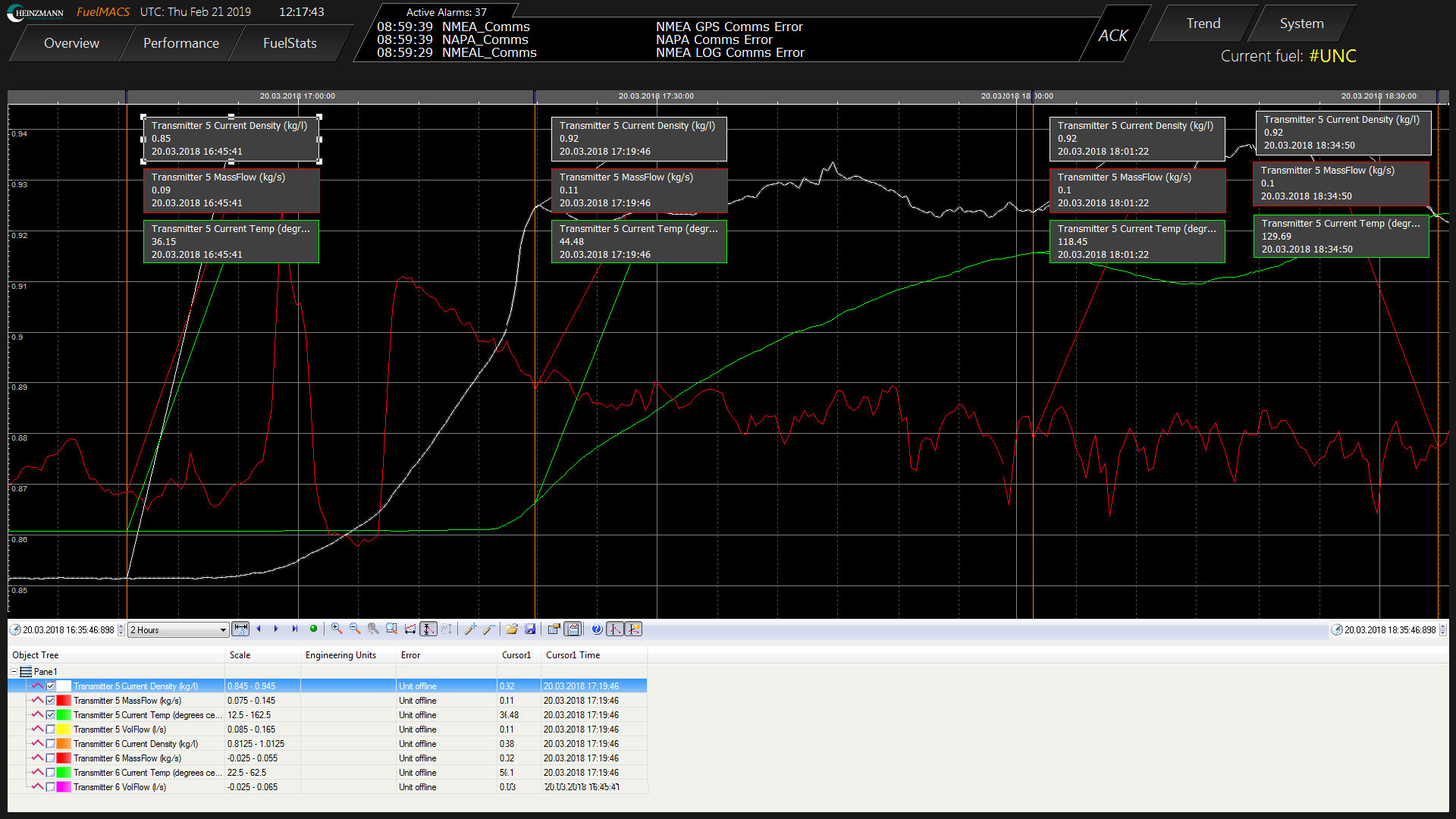

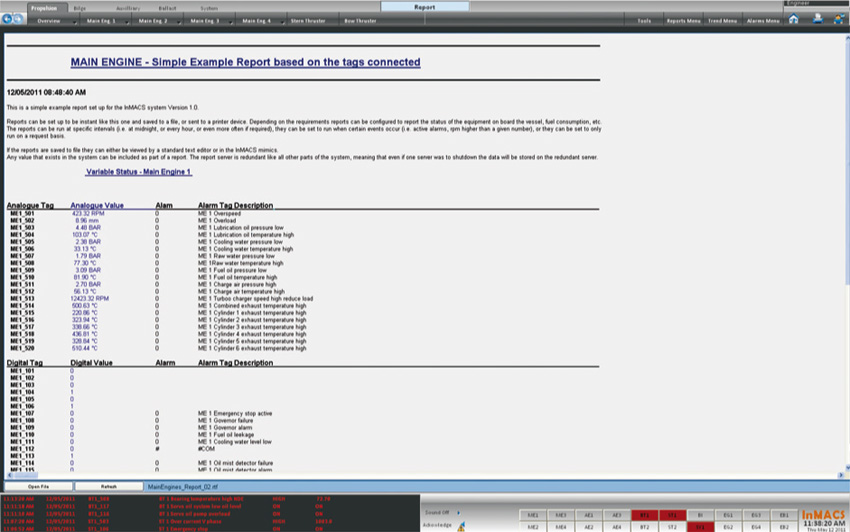

SeaMACS Integrated Automation Systems

One of the main benefits of the SeaMACS is the system scalability. It can be delivered both as a stand-alone alarm and monitoring system, as well as a fully Integrated Automation System (IAS) where the user will monitor as well as control.

Integrated Vessel Control for merchant marine, offshore and navy

SeaMACS IAS Benefits

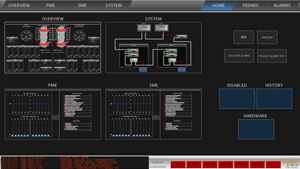

Reliability through redundant architecture

- Redundant architecture allows for safe operation and minimum downtime of the system

- Providing optimum reliability

- Avoids costs and damage to equipment induced by downtime

- Redundancy both at top level and lower level as standard

Scalability of network architecture

- Ethernet-based system allows for efficient handling of large amounts of data

- Meets future requirements for SCADA networks and is transparent and scalable

- Can easily be expanded or modified for future upgrades or add-ons without having to modify existing system hardware or software

Intuitivity and connectivity of user-interfaces

- The user-interface helps the operator easily navigate within the IAS

- Over 150 communication drivers included in the software

- Allowing for interfacing between over 300 different types of I/O devices, PLCs and other systems